Featured Questions

Display protection - a comprehensive explanation and an overview

What is a display film and why is it useful?

Screen protectors are specially made films that are occasionally used as a protective layer to protect the display. They can also be produced and applied in a suitable form using various methods. The purpose of a screen protector, also known as a display film, touch film, touchscreen film, or touch protection film (no universally accepted term has been established), is to effectively protect the device's display from damage such as scratches and scrapes, and even significantly reduce the risk of display breakage. Additionally, screen protectors also protect against chemicals such as cleaning agents or disinfectants, dirt and grease, as well as sweat and skin oils.

Protective effect screen protection

The display of the mobile phone is one of the elements of a smartphone that is most often affected. Especially in case of falls or impacts, the display can quickly break or get scratched, which consequently restricts or even makes the functionality impossible. A screen protector provides a protective effect, protecting the screen from external influences such as display scratches and ensuring that the phone remains functional for a long time. Coins, keys, or other hard, pointed objects like small stones or sand can scratch a smartphone screen. If the phone falls to the ground, the screen can even shatter. This is not only unpleasant, but repairing the display can sometimes be extremely expensive. Everyone knows the dreaded spiderweb crack on a phone screen! Therefore, an additional protection with a Neoxum anti-glare film or a transparent screen protector is highly recommended.

A defective screen, especially in touchscreen devices, renders the device completely unusable. An expensive display repair or touchscreen repair is undoubtedly the consequence, unless purchasing a new device is a more economically viable solution. Undoubtedly frustrating and expensive, and in the case of total loss, not particularly environmentally desirable, as:

1. The old device becomes electronic waste.

2. The disposal of electronic devices is still not reliably solved.

3. The electronic device usually has to be sent in for repair (at least, one has to do without the device for a few days).

Better and significantly more cost-effective is the preventive protection of expensive equipment with professional display protection, for example from Neoxum. There are fundamentally two different types of display protection:

1. Flexible display protection, made of film or hybrid glass.

2. Brittle display protection made of pure glass, such as tempered glass.

Both protect displays and screens from scratches and damage.

Higher resale value for used devices

When signing a mobile phone contract with popular durations of 2 to 4 years, a new smartphone is often included. When extending an existing contract, one usually receives a brand new device. The previous smartphone is no longer desired and is usually sold or given away. Scratches, especially on the screen, reduce the resale value. By using high-quality display protection from Neoxum, such as display film, anti-glare OnScreen hybrid glass, or transparent OnScreen hybrid glass, the display or display glass remains intact and one can obtain a higher selling price.

Quality of the display protection

For the quality of a display film, surface hardness, material thickness, transmission, and also the sensitivity change of the touch-sensitive screen are crucial. The harder the display protection surface, the more resistant it is to scratch marks and mechanical stress, such as rubbing or scraping. Typically, the hardness level of the display protection surface is indicated in pencil hardness H. But elasticity also plays an important role: We know this from the environment. Trees sway in the storm and yield to the energy of the storm. Even in extreme storms, healthy trees usually resist the forces of nature by yielding smoothly and flexibly.

Bamboo and Display Protection - an analogy

A vivid example is the astonishing bamboo scaffolding used in Asian construction. The natural material (bamboo is a grass!) is incredibly flexible and elastic, yet very strong. Entire skyscrapers are built using bamboo scaffolding. In contrast, rigid steel scaffolding can only withstand forces up to a certain degree before inevitably collapsing. Only the movable bamboo scaffolding is so stable that it can withstand heavy loads, such as hurricanes. The responsible factor for these extraordinary properties is the modulus of elasticity.

What does all of this have to do with display protection?

Stiff protection for glass displays (referred to as tempered glass) certainly has an exceptionally hard surface to protect against scratches and scrapes. Currently, the trend is for a product called "panzer glass" (also known as armored glass, real glass, or hard glass protection). This is a display protector made solely of glass. Panzer glass is often referred to as shock-resistant display protection glass or anti-shock glass. However, it is sometimes necessary to question this advertised cushioning feature. When suddenly subjected to force (an impact), such as a fall or a pointed object with localized pressure, a blow or impact with a screwdriver, etc. (the device falls with the monitor onto a hard surface), display protection made solely of glass tends to break quite quickly. Unfortunately, this usually results in small and larger sharp and jagged fragments.

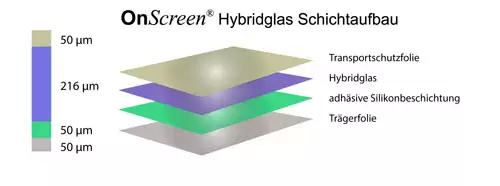

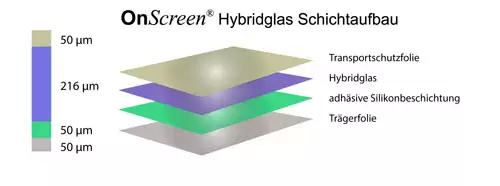

Display protection in industrial quality

Especially in the field of industrial display protection, therefore, armored glass or also called panzerglass, flexoglass or sometimes only protective glass, has not established itself because occupational safety plays an enormously important role here. Neoxum offers the answer with OnScreen Hybrid Glass: the hybrid material has a glass-hard surface with 9H and yet is flexible like a screen protector film. The combination of glass with an intermediate layer of film does not break and behaves more like safety glass or laminated glass. Obviously, the protective films available on the market for displays differ in their composition. A second-rate film cannot withstand sharp objects. For example, display films, screen protectors consisting exclusively of glass, and hybrid glass are currently successfully used in the following commercial segments.

-

Touchscreens and CNC milling, laser machines, NC controlled embossing machines, measuring devices for example for the glass slides of the company Keyence.

-

Agricultural machinery such as combine harvesters, tractors, and milk milking machines, which are now controlled by touch functionality on control panels.

-

Clinics, hospitals, nursing homes, and universities that need to have medical and veterinary examination equipment and patient screens that are anti-glare, protective, and disinfectable.

-

Industrial tablets, industrial mobile phones, and industrial smartphones

Adhesion-based display protection with long-lasting effect

Adhesion force on smooth surfaces

High-quality screen protection in general and glass screen protection, such as OnScreen Hybrid Glass, adheres solely through adhesive force to the surface of the display. An extremely strong adhesive effect is achieved through a "nanometer-scale suction cup", without the use of adhesives, which completely prevents slipping or falling off. Nevertheless, adhesive films and also OnScreen Hybrid Glass can be easily removed from a display without leaving any residue. In this case, one only needs to pull up the screen protector at one edge with a fingernail and then remove it diagonally backwards. The relationship between adhesive force and the forces required to remove it can be understood approximately as follows. If two flat glass plates are placed directly on top of each other, the air gap between them is completely displaced. The surrounding air pressure pushes the plates together tightly. If one wants to separate the two, it is not possible with human forces. However, if a trick is used and the glass plates are pushed apart, the separation is very easy.

Physical Chemical Forces

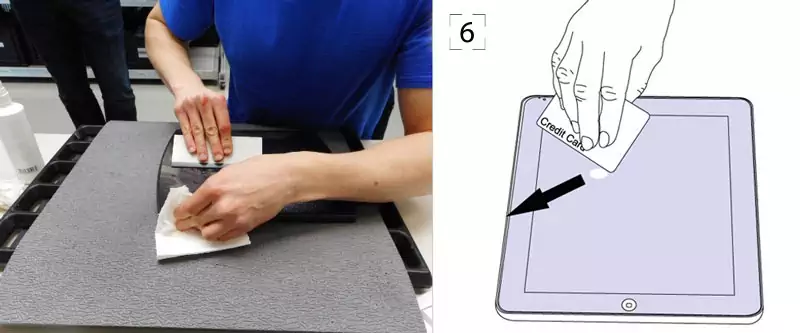

Several factors are crucial for the adhesive effect of high-quality display protection on monitor surfaces. Adhesion is a fundamental phenomenon in the molecular influence range, which arises from polar interactions at interfaces, in our case the interface between the display surface and the silicone adhesive layer of the display protection.

In particular, the so-called Van der Waals forces between molecules of the screen surface and molecules of the adhesive layer (the very thin silicone adhesive layer) are primarily responsible for the strong adhesion to smooth surfaces. The decisive factor for the adhesive force is the spatial proximity of the two surfaces. The silicone adhesive layer of the Neoxum display protector, or surface protector, is designed in such a way that Neoxum display films, as well as the OnScreen hybrid glass, show an exceptionally high adhesive effect on numerous smooth materials such as plastic, metal, and glass. The adhesive film and the hybrid glass can be removed without leaving any residue from all materials. No adhesive or glue is used.

Different types of display films

Transparent, translucent, and reflection-reducing display protection

Transparent display protector

In completely transparent version, the display protector is barely visible. The ultra-clear display protector protects the display like a second skin. Colors are reproduced true to life. The transparent protection of the display is hardly noticeable on high-quality items. Most untrained eyes do not even realize that an ultra-clear display protector film or a transparent on-screen hybrid glass is applied on the display. The functionality of the touch-sensitive screen is not affected in any way by the film or the hybrid glass. The touch function works just as it should even with the applied display protector. Neoxum transparent display films and hybrid glasses are equipped with a repellent anti-fingerprint layer that significantly reduces unsightly fingerprints.

Anti-glare screen protector

With an anti-reflective film, reflections on the display surface are effectively minimized: the screen is de-glared and protected from display damage by the additional protective layer. The anti-reflective surface performs excellent services in bright environments, especially when working outdoors. The screen can be significantly better recognized. No more annoying and obstructive reflections..

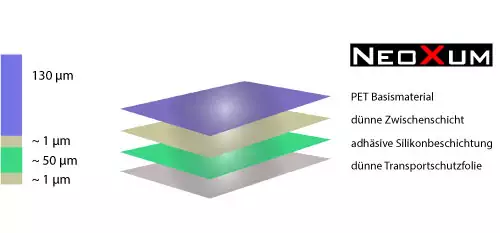

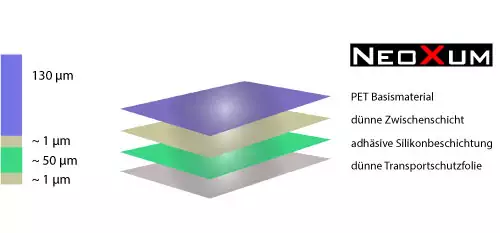

Structure and construction of display protection

Screen protectors consist of different layers that are specifically adapted for their task. An adhesive layer allows it to stick to the monitor surface. It is essential to have an easy and bubble-free installation. The actual protective layer, made of PET high-performance film, pure glass (which is very brittle and prone to breaking), or a hybrid material with a glass-like surface and elastic special polymer (OnScreen Hybrid Glass), is responsible for protecting the display from damage. The usability of the touch-sensitive screen is not restricted by the additional efficient protective layer. Even displays made of tempered glass (often referred to as Gorilla Glass, armored glass, or armored glass) are not immune to scratches or other signs of use if they are subjected to exceptionally hard objects. Below is a brief overview of hardness levels.

Surface hardness of display protection or how hard is display protection actually?

The classification of how hard a display film or display glass is, is measured in the world of surface and display protection in Mohs surface hardness grades. The following table shows different hardness grades of surfaces and compares them to a naturally occurring material and an everyday object that would scratch the display protection.

Hardness levels of materials |

|

|

| Hardness level H | as hard as | Beschreibung Härtegrad |

|

1H |

TalkMg3[(OH)2/Si4O10] |

Material can easily be pressed in with a fingernail, film made of polypropylene or polyethylene. |

|

2H |

Gips CaS04*2H20 |

The material can still be pressed in with a fingernail. |

|

3H |

Kalkspat CaC03 (Calcit) |

high-quality display protective film made of PET (Polyethylenterephtalate) |

|

4H |

Flussspat CaF2 |

high-quality display film made of PET (Polyethylenterephtahlat) |

|

5H |

Apatit Ca5[(F,CI,0H)/(P04)2] |

simple window glass |

|

6H |

Feldspat KAISi3Og |

Material can be scratched with a simple kitchen knife. |

|

7H |

Quarz Si02 |

as hard as tempered glass, Gorilla Glass, armored glass or OnScreen Hybrid glass from Neoxum |

|

8H |

Topas AI2[F2/Si04] |

|

|

9H |

Korund Al203 |

as hard as sapphire glass, for example: watch glass for high-quality watches; jewelry, is usually processed with diamond or cut with the help of lasers |

|

10H |

Diamant C (Carbon modification) |

hardest widely known material, diamond can only be polished or cut with diamond |

Curved displays - 2D - 2.5D - 3D protective glasses

In addition to the distinction between clear and anti-glare display films and protective coatings made of glass or a glass-plastic composite (OnScreen Hybrid Glass), there are other differences that can be indicated with D-designations: 2D films only cover the display, 2.5D films also protect the edges of monitors with highly curved displays (CAUTION: risk of breakage), and 3D films extend beyond the screen (CAUTION: risk of breakage at the edge).

Protective films applied by the device manufacturer

Factory-installed protective films are mostly made of polypropylene (PP) or polyethylene (PE) or even polyvinyl chloride (PVC), and are more suitable as transport protective films rather than additional display protection. These transport protective films, which are mostly not precisely shaped, are intended to protect the display from damage during final assembly and packaging. Once this functionality is fulfilled, the very easily adhesive protective film can be effortlessly removed from the display after the device is purchased. However, there are already exceptional cases where mobile phone manufacturers have applied good display protective films to the mobile phone screens.

Cheap screen protectors in packs of 3, 6, 9, or 12.

Display foils are small useful helpers against damage to touch displays and scratch-sensitive surfaces. The display protection is usually made of PE (polyethylene), PP (polypropylene), or PVC (polyvinyl chloride) in inexpensive protective films. The adhesion to surfaces is usually achieved by using adhesive (acrylates or modified acrylate adhesives), which are applied in very thin layers (usually less than 10-20 g adhesive per square meter of film). Alternatively, for slightly more efficient display protection made of the aforementioned materials, an adhesive silicone layer is used as an adhesive (adhesive but not sticky adhesive layer).

Cheap thin protective films

What all three inexpensive to very cost-effective screen protectors have in common is the fact that they are relatively thin. The majority of affordable screen protectors have a thickness of no more than 60 microns (60 µm), which is equivalent to 0.06 mm. In addition, protective films made of PE and PP are very flexible and ductile. This means that the soft polymer can easily deform with minimal force (better: pressure = force per area). If the applied force exceeds a certain maximum (for example, a pen scratches the thin protective film), an object (jeans rivet, ballpoint pen, pen, stone, key, etc.) can quickly penetrate the thin polymer protective layer. The underlying display will inevitably be damaged. Furthermore, inexpensive screen protectors have minimal resistance to horizontal shear forces: they can easily be stretched. During the stretching process, the film material becomes thinner until it tears when the stretching capacity is exceeded. The low durability and load-bearing capacity is the reason why cheap providers usually offer packs of 3, 6, 9, or even 12 screen protectors for a low price. The protective films wear out relatively quickly and need to be replaced.

Insufficient surface hardness of cheap screen protectors

The low surface hardness of cheap films quickly leads to the surface of the inexpensive display film itself being heavily scratched, making it difficult to read anything on the display. Cheap screen protectors are mostly multi-layered and punched into shape with cutting plates in Asia. This can sometimes result in crushing at the cutting edges. This not only affects the fit, but also damages the adhesive layer. Sometimes the inexpensive display film does not adhere to the edges of the display and protrudes. Such screen protectors do not meet any commercial or industrial quality standards. We recommend using high-quality and professional screen protectors for touch displays.

Professional screen protection

Professional screen protectors are usually made of PET (Polyethylene terephthalate), a polyester material. PET has outstanding optical properties, high tear strength, and an E-modulus of 4500 N·mm−2 longitudinally and transversely. This means that with a thickness of about 0.1-0.13 mm, which is suitable for a high-quality screen protection, it provides a very secure and durable protection for the display. Sharp objects do not easily penetrate the durable protective layer. The display underneath the screen protector is protected with high efficiency. PET screen protectors are highly resistant to chemicals. In addition, PET screen protectors are very resistant to high and low temperatures. We have outlined the decisive properties of Neoxum display films in our technical data sheet. Professional display films from Neoxum are used, for example, in the food industry or in hospitals, where the screens need to be regularly disinfected to remove germs. The disinfection of the displays does not harm the touch displays due to the protective mechanism of the screen protector, or the hybrid glass.

The surface of good display films has a surface hardness of 3H. Scratches on the display film are not avoidable with heavy and intense use in industrial or commercial settings. However, a high-quality display protector from Neoxum protects against scratches, damage, chemicals, including cleaning agents, without negatively affecting the touch function.

Why is a good display protection fit essential?

Professional screen protectors and OnScreen Hybrid Glass from Neoxum are produced in Germany using advanced precision laser machines. The small cutouts and cutouts on the device display are different sensors of the device. For example, a mobile phone may have light sensors, proximity sensors, multiple camera lenses in the case of new phones, microphone inputs, speaker outputs, and several other cutouts.

In order not to negatively affect the function even with a screen protector, all cutouts for the device's sensors are laser-cut. This is especially relevant for the light and proximity sensors. The automatic shutdown of the display during a phone call and the brightness control of the display are regulated with the help of photosensitive sensors. For Neoxum screen protectors as well as OnScreen Hybrid Glass, the measurements are always taken on the original device display. As already explained, all cutouts are important for the measurements. But the dimensions must also be accurately measured digitally. There are manufacturers who use dummy devices (without electronics, only device housing and display) for measurement. However, significant deviations from the original display can occur. For curved displays, Neoxum screen protectors are cut with the help of lasers so that neither the Neoxum protective film nor the Neoxum OnScreen Hybrid Glass protrude beyond the edges. In general, Hybrid Glass adheres more strongly to the display surface and is therefore very suitable for curved displays. An adhesive layer made of very thin silicone is responsible for the adhesion to the monitor surface. The adhesion is based on the physical principle of adhesion. We have already explained the adhesion based on forces in the nanometer range in more detail in an article on adhesion and adhesion of protective films on display surfaces.

Environmental impact screen protector

Prevention of electronic waste through high-quality display protection

Naturally, a high-quality screen protector ensures an extended device life because the control unit, the screen, is well protected. Broken or shattered device screens inevitably lead to expensive repairs or even device replacement. Often, it is simply too costly to repair the display because new devices cost almost the same. Consequently, broken displays or screens that have become unusable due to wear and tear or a display defect are ecologically very undesirable. Precautionary screen protection prevents display damage. Scratches and damage to the screen have no chance anymore, and in the event of a fall, the likelihood is much greater that a protected display will remain intact. The environmental impact is higher with screen protection than without.

Plastic recycling of display protection films

Display foils, on the other hand, are made of plastic. Inexpensive display protective foils made of PP, PE or PVC are not particularly resistant and therefore need to be replaced regularly. This in turn causes avoidable plastic waste. PP and PE can be recycled. Thermal utilization is also possible, leaving only water and carbon dioxide. However, we all produce far too much (cheap) plastic waste. It is better to use high-quality PET display foils, which are very robust and durable. In addition, PET display foils can be collected separately and recycled, for example, into beverage bottles. PVC protective foils have a rather poor ecological balance. PVC contains chloride (PVC = polyvinyl chloride), which reacts with health-hazardous dioxins, furans, and hydrochloric acid during thermal utilization (waste incineration). Therefore, exhaust gases contaminated with PVC must be cleaned using elaborate cleaning processes. In the long run, it is more sustainable to avoid inexpensive PVC display foils.

Apply a screen protector to the display

Dust-free environment

The essential rule when installing screen protectors or glass screen protectors is to take some time and ensure a dust-free environment. A dust-free environment can be easily created at home in the bathroom. After showering or bathing, the air in the room is relatively humid and there is usually little dust in the air. Alternatively, you can go into a well-ventilated room that is free from drafts. One should not wear linty clothing, such as a wool sweater.

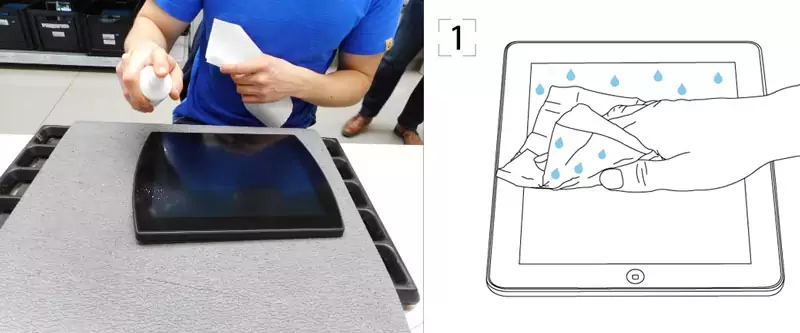

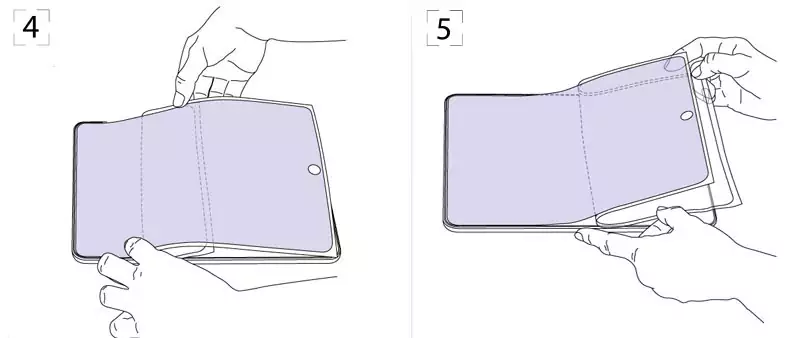

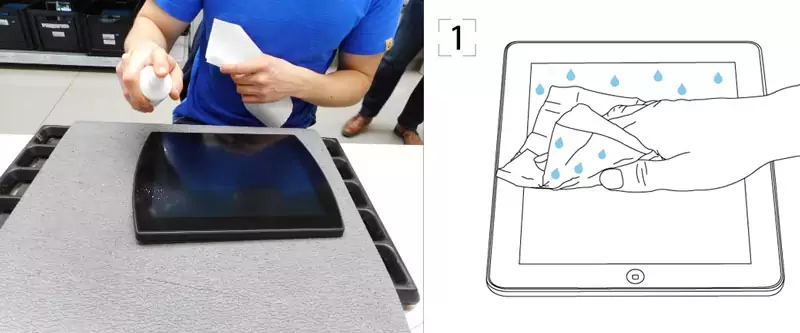

Cleaning the touchscreen

How a screen protector or also known as tempered glass, hybrid glass or glass film is carefully applied to the respective device display should be described in a detailed instruction manual for high-quality screen protection. The most essential aspect is that the monitor is free of grease and dust. Usually, a cleaning cloth is also included as an accessory with branded products. For this purpose, Neoxum provides a wet wipe for screen cleaning and a dry cloth with Neoxum display films, as well as OnScreen hybrid glass.

A microfiber cloth alone is not very suitable for removing fingerprints or grease. Armed only with a microfiber cloth, one would rather smear fingerprints on the display. In this case, it is advisable to use a suitable display cleaner liquid. Furthermore, it is recommended to clean the display from dust with the included cleaning accessories. Cheap microfiber cloths generate static electricity, which attracts even more dust to the display. In this case, it is advisable to also use an antistatic screen cleaning solution (screen cleaner) to remove dust.

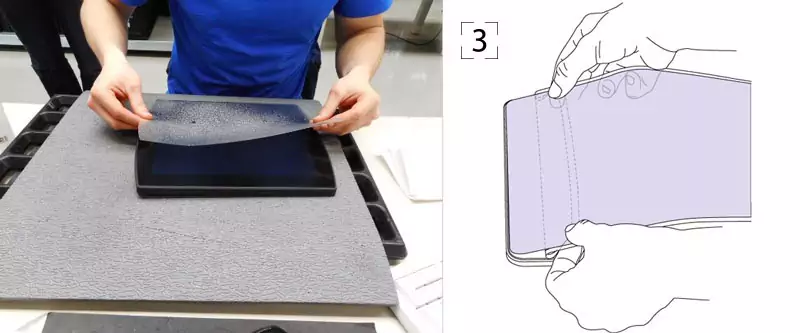

Individual steps of the display protection assembly

Does the screen protector fit?

In the first step, start by placing the screen protector product, whether it's ultra clear or anti-glare, on the display to be protected to check the dimensions. Do all the cutouts fit? Are there cutouts for the camera lens, microphone, speaker outlet, etc.? Does the length and width fit? The backing film should not be removed yet!

IMPORTANT: Usually, the screen protector is cut slightly smaller than the dimensions from edge to edge of the display to make installation easier. The screen protector should be approximately 0.5-1 mm smaller all around than the display itself. This is to facilitate installation, depending on the size of the display.

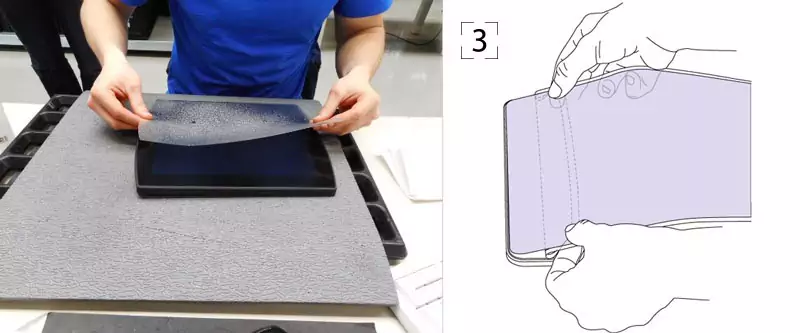

Partial removal of the carrier film

In the next step, a partial (approx. 2-4 cm) removal of the display protector from the carrier film will be carried out.

Different manufacturers have developed more or less unproblematic methodologies here to facilitate the removal of the actual display protection from the carrier film. All Neoxum products, display protection films, as well as OnScreen Hybrid Glass, are produced using the so-called Kiss-Cut process. In this process, all cut-outs are cut out. However, the outer contour is only laser-cut deep enough to accurately cut through the display protection material without also cutting through the underlying carrier film. The display protection can then be easily removed like a label. It is very important to touch the now exposed silicone adhesive layer as little as possible with your fingers.

Apply screen protector

The silicone-coated adhesive side of the screen protector is now placed on the cleaned, dust- and grease-free display surface at an angle of about 30-45° along one edge and carefully applied piece by piece to the touchscreen.

When using a screen protector larger than 15 inches diagonally, it is advantageous to align it along one of the long edges. At the same time, gradually peel off the backing film. This way, the glass display film or screen protector is applied to the surface without any air bubbles forming. Air bubbles can be smoothed out towards the edges using a thumb nail or a plastic card, such as a debit card.

If, despite all caution, a dust particle is found between the display surface and the screen protector after installation, it can be easily removed using a trick: Cut a piece of adhesive tape (approximately 5-7 cm long) from a brand like TESA or SCOTCH and stick it to the edge closest to the dust particle, with only one half attached to the screen protector. Then, lift the screen protector easily using the other unattached end. With a second piece of adhesive tape, which has been rolled into a loop with the sticky side facing outwards, the dust particle can now be removed from the display surface.

SSL encryptionYour personal data that you provide during the ordering process will be transmitted in encrypted form and is thus protected against misuse. The modern shop system automatically establishes a so-called Secure Socket Layer (SSL) connection every time you call up your browser (also mobile!). SSL is a method where your personal data is strongly encrypted so that it cannot be read by unauthorized third parties during transmission on the Internet. Any payment option offered in the shop is SSL encrypted to protect your data from misuse. Look for the Internet address in the address bar of your browser: it must always show "https://" (for SSL - Secure Socket Layer). In addition, the secured connection is usually indicated by a closed padlock symbol in the status bar of the web browser. |

|

Hallo,

Gerne können wir Ihnen ein Testmuster anbieten.

Sie können dieses ganz einfach über unseren Online Shop erwerben.

Testmuster für OnScreen Hybridglas

Testmuster für Neoxum Displayschutzfolien

Precise laser cutting

Neoxum films are already precisely cut to fit a specific model, such as iPhone 8, by laser. Both the anti-reflective and clear protective films are cut to fit precisely using state-of-the-art laser cutting systems. All cutouts for camera lenses, microphones, or speakers are taken into account, as well as special corner radii or display shapes and dimensions.

Precision

A manufacturer and model dependent screen protector is manufactured with an accuracy of 0.1 mm, taking into account optimal installation and laser-cutting all necessary edges, radii, and cutouts.

Special sizes and custom-made products

Highest precision up to 1600 mm x 1000 mm (approximately 75 inches)

Our state-of-the-art laser systems allow us to custom manufacture special dimensions up to 1600 mm x 1000 mm (approximately 75 inches) directly for our customers. Whether you have specific requirements for size or shape, we are able to fulfill your wishes.

Our experienced team works closely with you to ensure that your special dimensions meet your exact requirements. We are happy to advise you on selecting the right material and optimal processing technique to achieve the best possible result.

Thanks to our modern laser systems, we can perform precise and high-quality cuts in the shortest amount of time. We place great importance on quality and accuracy, being ISO 9001:2015 certified, and ensure that each component meets the highest standards.

Protective film up to 3.5 meters in length

In addition, larger formats up to 3500 mm x 1040 mm are possible. However, we have to make a small compromise in terms of accuracy: we can specify the precision of these very large (or huge?) display protection products with ± 3 mm.

Faq Sections

Hallo,

Gerne können wir Ihnen ein Testmuster anbieten.

Sie können dieses ganz einfach über unseren Online Shop erwerben.

Testmuster für OnScreen Hybridglas

Testmuster für Neoxum Displayschutzfolien

Precise laser cutting

Neoxum films are already precisely cut to fit a specific model, such as iPhone 8, by laser. Both the anti-reflective and clear protective films are cut to fit precisely using state-of-the-art laser cutting systems. All cutouts for camera lenses, microphones, or speakers are taken into account, as well as special corner radii or display shapes and dimensions.

Precision

A manufacturer and model dependent screen protector is manufactured with an accuracy of 0.1 mm, taking into account optimal installation and laser-cutting all necessary edges, radii, and cutouts.

Special sizes and custom-made products

Highest precision up to 1600 mm x 1000 mm (approximately 75 inches)

Our state-of-the-art laser systems allow us to custom manufacture special dimensions up to 1600 mm x 1000 mm (approximately 75 inches) directly for our customers. Whether you have specific requirements for size or shape, we are able to fulfill your wishes.

Our experienced team works closely with you to ensure that your special dimensions meet your exact requirements. We are happy to advise you on selecting the right material and optimal processing technique to achieve the best possible result.

Thanks to our modern laser systems, we can perform precise and high-quality cuts in the shortest amount of time. We place great importance on quality and accuracy, being ISO 9001:2015 certified, and ensure that each component meets the highest standards.

Protective film up to 3.5 meters in length

In addition, larger formats up to 3500 mm x 1040 mm are possible. However, we have to make a small compromise in terms of accuracy: we can specify the precision of these very large (or huge?) display protection products with ± 3 mm.

SSL encryptionYour personal data that you provide during the ordering process will be transmitted in encrypted form and is thus protected against misuse. The modern shop system automatically establishes a so-called Secure Socket Layer (SSL) connection every time you call up your browser (also mobile!). SSL is a method where your personal data is strongly encrypted so that it cannot be read by unauthorized third parties during transmission on the Internet. Any payment option offered in the shop is SSL encrypted to protect your data from misuse. Look for the Internet address in the address bar of your browser: it must always show "https://" (for SSL - Secure Socket Layer). In addition, the secured connection is usually indicated by a closed padlock symbol in the status bar of the web browser. |

|

Display protection - a comprehensive explanation and an overview

What is a display film and why is it useful?

Screen protectors are specially made films that are occasionally used as a protective layer to protect the display. They can also be produced and applied in a suitable form using various methods. The purpose of a screen protector, also known as a display film, touch film, touchscreen film, or touch protection film (no universally accepted term has been established), is to effectively protect the device's display from damage such as scratches and scrapes, and even significantly reduce the risk of display breakage. Additionally, screen protectors also protect against chemicals such as cleaning agents or disinfectants, dirt and grease, as well as sweat and skin oils.

Protective effect screen protection

The display of the mobile phone is one of the elements of a smartphone that is most often affected. Especially in case of falls or impacts, the display can quickly break or get scratched, which consequently restricts or even makes the functionality impossible. A screen protector provides a protective effect, protecting the screen from external influences such as display scratches and ensuring that the phone remains functional for a long time. Coins, keys, or other hard, pointed objects like small stones or sand can scratch a smartphone screen. If the phone falls to the ground, the screen can even shatter. This is not only unpleasant, but repairing the display can sometimes be extremely expensive. Everyone knows the dreaded spiderweb crack on a phone screen! Therefore, an additional protection with a Neoxum anti-glare film or a transparent screen protector is highly recommended.

A defective screen, especially in touchscreen devices, renders the device completely unusable. An expensive display repair or touchscreen repair is undoubtedly the consequence, unless purchasing a new device is a more economically viable solution. Undoubtedly frustrating and expensive, and in the case of total loss, not particularly environmentally desirable, as:

1. The old device becomes electronic waste.

2. The disposal of electronic devices is still not reliably solved.

3. The electronic device usually has to be sent in for repair (at least, one has to do without the device for a few days).

Better and significantly more cost-effective is the preventive protection of expensive equipment with professional display protection, for example from Neoxum. There are fundamentally two different types of display protection:

1. Flexible display protection, made of film or hybrid glass.

2. Brittle display protection made of pure glass, such as tempered glass.

Both protect displays and screens from scratches and damage.

Higher resale value for used devices

When signing a mobile phone contract with popular durations of 2 to 4 years, a new smartphone is often included. When extending an existing contract, one usually receives a brand new device. The previous smartphone is no longer desired and is usually sold or given away. Scratches, especially on the screen, reduce the resale value. By using high-quality display protection from Neoxum, such as display film, anti-glare OnScreen hybrid glass, or transparent OnScreen hybrid glass, the display or display glass remains intact and one can obtain a higher selling price.

Quality of the display protection

For the quality of a display film, surface hardness, material thickness, transmission, and also the sensitivity change of the touch-sensitive screen are crucial. The harder the display protection surface, the more resistant it is to scratch marks and mechanical stress, such as rubbing or scraping. Typically, the hardness level of the display protection surface is indicated in pencil hardness H. But elasticity also plays an important role: We know this from the environment. Trees sway in the storm and yield to the energy of the storm. Even in extreme storms, healthy trees usually resist the forces of nature by yielding smoothly and flexibly.

Bamboo and Display Protection - an analogy

A vivid example is the astonishing bamboo scaffolding used in Asian construction. The natural material (bamboo is a grass!) is incredibly flexible and elastic, yet very strong. Entire skyscrapers are built using bamboo scaffolding. In contrast, rigid steel scaffolding can only withstand forces up to a certain degree before inevitably collapsing. Only the movable bamboo scaffolding is so stable that it can withstand heavy loads, such as hurricanes. The responsible factor for these extraordinary properties is the modulus of elasticity.

What does all of this have to do with display protection?

Stiff protection for glass displays (referred to as tempered glass) certainly has an exceptionally hard surface to protect against scratches and scrapes. Currently, the trend is for a product called "panzer glass" (also known as armored glass, real glass, or hard glass protection). This is a display protector made solely of glass. Panzer glass is often referred to as shock-resistant display protection glass or anti-shock glass. However, it is sometimes necessary to question this advertised cushioning feature. When suddenly subjected to force (an impact), such as a fall or a pointed object with localized pressure, a blow or impact with a screwdriver, etc. (the device falls with the monitor onto a hard surface), display protection made solely of glass tends to break quite quickly. Unfortunately, this usually results in small and larger sharp and jagged fragments.

Display protection in industrial quality

Especially in the field of industrial display protection, therefore, armored glass or also called panzerglass, flexoglass or sometimes only protective glass, has not established itself because occupational safety plays an enormously important role here. Neoxum offers the answer with OnScreen Hybrid Glass: the hybrid material has a glass-hard surface with 9H and yet is flexible like a screen protector film. The combination of glass with an intermediate layer of film does not break and behaves more like safety glass or laminated glass. Obviously, the protective films available on the market for displays differ in their composition. A second-rate film cannot withstand sharp objects. For example, display films, screen protectors consisting exclusively of glass, and hybrid glass are currently successfully used in the following commercial segments.

-

Touchscreens and CNC milling, laser machines, NC controlled embossing machines, measuring devices for example for the glass slides of the company Keyence.

-

Agricultural machinery such as combine harvesters, tractors, and milk milking machines, which are now controlled by touch functionality on control panels.

-

Clinics, hospitals, nursing homes, and universities that need to have medical and veterinary examination equipment and patient screens that are anti-glare, protective, and disinfectable.

-

Industrial tablets, industrial mobile phones, and industrial smartphones

Adhesion-based display protection with long-lasting effect

Adhesion force on smooth surfaces

High-quality screen protection in general and glass screen protection, such as OnScreen Hybrid Glass, adheres solely through adhesive force to the surface of the display. An extremely strong adhesive effect is achieved through a "nanometer-scale suction cup", without the use of adhesives, which completely prevents slipping or falling off. Nevertheless, adhesive films and also OnScreen Hybrid Glass can be easily removed from a display without leaving any residue. In this case, one only needs to pull up the screen protector at one edge with a fingernail and then remove it diagonally backwards. The relationship between adhesive force and the forces required to remove it can be understood approximately as follows. If two flat glass plates are placed directly on top of each other, the air gap between them is completely displaced. The surrounding air pressure pushes the plates together tightly. If one wants to separate the two, it is not possible with human forces. However, if a trick is used and the glass plates are pushed apart, the separation is very easy.

Physical Chemical Forces

Several factors are crucial for the adhesive effect of high-quality display protection on monitor surfaces. Adhesion is a fundamental phenomenon in the molecular influence range, which arises from polar interactions at interfaces, in our case the interface between the display surface and the silicone adhesive layer of the display protection.

In particular, the so-called Van der Waals forces between molecules of the screen surface and molecules of the adhesive layer (the very thin silicone adhesive layer) are primarily responsible for the strong adhesion to smooth surfaces. The decisive factor for the adhesive force is the spatial proximity of the two surfaces. The silicone adhesive layer of the Neoxum display protector, or surface protector, is designed in such a way that Neoxum display films, as well as the OnScreen hybrid glass, show an exceptionally high adhesive effect on numerous smooth materials such as plastic, metal, and glass. The adhesive film and the hybrid glass can be removed without leaving any residue from all materials. No adhesive or glue is used.

Different types of display films

Transparent, translucent, and reflection-reducing display protection

Transparent display protector

In completely transparent version, the display protector is barely visible. The ultra-clear display protector protects the display like a second skin. Colors are reproduced true to life. The transparent protection of the display is hardly noticeable on high-quality items. Most untrained eyes do not even realize that an ultra-clear display protector film or a transparent on-screen hybrid glass is applied on the display. The functionality of the touch-sensitive screen is not affected in any way by the film or the hybrid glass. The touch function works just as it should even with the applied display protector. Neoxum transparent display films and hybrid glasses are equipped with a repellent anti-fingerprint layer that significantly reduces unsightly fingerprints.

Anti-glare screen protector

With an anti-reflective film, reflections on the display surface are effectively minimized: the screen is de-glared and protected from display damage by the additional protective layer. The anti-reflective surface performs excellent services in bright environments, especially when working outdoors. The screen can be significantly better recognized. No more annoying and obstructive reflections..

Structure and construction of display protection

Screen protectors consist of different layers that are specifically adapted for their task. An adhesive layer allows it to stick to the monitor surface. It is essential to have an easy and bubble-free installation. The actual protective layer, made of PET high-performance film, pure glass (which is very brittle and prone to breaking), or a hybrid material with a glass-like surface and elastic special polymer (OnScreen Hybrid Glass), is responsible for protecting the display from damage. The usability of the touch-sensitive screen is not restricted by the additional efficient protective layer. Even displays made of tempered glass (often referred to as Gorilla Glass, armored glass, or armored glass) are not immune to scratches or other signs of use if they are subjected to exceptionally hard objects. Below is a brief overview of hardness levels.

Surface hardness of display protection or how hard is display protection actually?

The classification of how hard a display film or display glass is, is measured in the world of surface and display protection in Mohs surface hardness grades. The following table shows different hardness grades of surfaces and compares them to a naturally occurring material and an everyday object that would scratch the display protection.

Hardness levels of materials |

|

|

| Hardness level H | as hard as | Beschreibung Härtegrad |

|

1H |

TalkMg3[(OH)2/Si4O10] |

Material can easily be pressed in with a fingernail, film made of polypropylene or polyethylene. |

|

2H |

Gips CaS04*2H20 |

The material can still be pressed in with a fingernail. |

|

3H |

Kalkspat CaC03 (Calcit) |

high-quality display protective film made of PET (Polyethylenterephtalate) |

|

4H |

Flussspat CaF2 |

high-quality display film made of PET (Polyethylenterephtahlat) |

|

5H |

Apatit Ca5[(F,CI,0H)/(P04)2] |

simple window glass |

|

6H |

Feldspat KAISi3Og |

Material can be scratched with a simple kitchen knife. |

|

7H |

Quarz Si02 |

as hard as tempered glass, Gorilla Glass, armored glass or OnScreen Hybrid glass from Neoxum |

|

8H |

Topas AI2[F2/Si04] |

|

|

9H |

Korund Al203 |

as hard as sapphire glass, for example: watch glass for high-quality watches; jewelry, is usually processed with diamond or cut with the help of lasers |

|

10H |

Diamant C (Carbon modification) |

hardest widely known material, diamond can only be polished or cut with diamond |

Curved displays - 2D - 2.5D - 3D protective glasses

In addition to the distinction between clear and anti-glare display films and protective coatings made of glass or a glass-plastic composite (OnScreen Hybrid Glass), there are other differences that can be indicated with D-designations: 2D films only cover the display, 2.5D films also protect the edges of monitors with highly curved displays (CAUTION: risk of breakage), and 3D films extend beyond the screen (CAUTION: risk of breakage at the edge).

Protective films applied by the device manufacturer

Factory-installed protective films are mostly made of polypropylene (PP) or polyethylene (PE) or even polyvinyl chloride (PVC), and are more suitable as transport protective films rather than additional display protection. These transport protective films, which are mostly not precisely shaped, are intended to protect the display from damage during final assembly and packaging. Once this functionality is fulfilled, the very easily adhesive protective film can be effortlessly removed from the display after the device is purchased. However, there are already exceptional cases where mobile phone manufacturers have applied good display protective films to the mobile phone screens.

Cheap screen protectors in packs of 3, 6, 9, or 12.

Display foils are small useful helpers against damage to touch displays and scratch-sensitive surfaces. The display protection is usually made of PE (polyethylene), PP (polypropylene), or PVC (polyvinyl chloride) in inexpensive protective films. The adhesion to surfaces is usually achieved by using adhesive (acrylates or modified acrylate adhesives), which are applied in very thin layers (usually less than 10-20 g adhesive per square meter of film). Alternatively, for slightly more efficient display protection made of the aforementioned materials, an adhesive silicone layer is used as an adhesive (adhesive but not sticky adhesive layer).

Cheap thin protective films

What all three inexpensive to very cost-effective screen protectors have in common is the fact that they are relatively thin. The majority of affordable screen protectors have a thickness of no more than 60 microns (60 µm), which is equivalent to 0.06 mm. In addition, protective films made of PE and PP are very flexible and ductile. This means that the soft polymer can easily deform with minimal force (better: pressure = force per area). If the applied force exceeds a certain maximum (for example, a pen scratches the thin protective film), an object (jeans rivet, ballpoint pen, pen, stone, key, etc.) can quickly penetrate the thin polymer protective layer. The underlying display will inevitably be damaged. Furthermore, inexpensive screen protectors have minimal resistance to horizontal shear forces: they can easily be stretched. During the stretching process, the film material becomes thinner until it tears when the stretching capacity is exceeded. The low durability and load-bearing capacity is the reason why cheap providers usually offer packs of 3, 6, 9, or even 12 screen protectors for a low price. The protective films wear out relatively quickly and need to be replaced.

Insufficient surface hardness of cheap screen protectors

The low surface hardness of cheap films quickly leads to the surface of the inexpensive display film itself being heavily scratched, making it difficult to read anything on the display. Cheap screen protectors are mostly multi-layered and punched into shape with cutting plates in Asia. This can sometimes result in crushing at the cutting edges. This not only affects the fit, but also damages the adhesive layer. Sometimes the inexpensive display film does not adhere to the edges of the display and protrudes. Such screen protectors do not meet any commercial or industrial quality standards. We recommend using high-quality and professional screen protectors for touch displays.

Professional screen protection

Professional screen protectors are usually made of PET (Polyethylene terephthalate), a polyester material. PET has outstanding optical properties, high tear strength, and an E-modulus of 4500 N·mm−2 longitudinally and transversely. This means that with a thickness of about 0.1-0.13 mm, which is suitable for a high-quality screen protection, it provides a very secure and durable protection for the display. Sharp objects do not easily penetrate the durable protective layer. The display underneath the screen protector is protected with high efficiency. PET screen protectors are highly resistant to chemicals. In addition, PET screen protectors are very resistant to high and low temperatures. We have outlined the decisive properties of Neoxum display films in our technical data sheet. Professional display films from Neoxum are used, for example, in the food industry or in hospitals, where the screens need to be regularly disinfected to remove germs. The disinfection of the displays does not harm the touch displays due to the protective mechanism of the screen protector, or the hybrid glass.

The surface of good display films has a surface hardness of 3H. Scratches on the display film are not avoidable with heavy and intense use in industrial or commercial settings. However, a high-quality display protector from Neoxum protects against scratches, damage, chemicals, including cleaning agents, without negatively affecting the touch function.

Why is a good display protection fit essential?

Professional screen protectors and OnScreen Hybrid Glass from Neoxum are produced in Germany using advanced precision laser machines. The small cutouts and cutouts on the device display are different sensors of the device. For example, a mobile phone may have light sensors, proximity sensors, multiple camera lenses in the case of new phones, microphone inputs, speaker outputs, and several other cutouts.

In order not to negatively affect the function even with a screen protector, all cutouts for the device's sensors are laser-cut. This is especially relevant for the light and proximity sensors. The automatic shutdown of the display during a phone call and the brightness control of the display are regulated with the help of photosensitive sensors. For Neoxum screen protectors as well as OnScreen Hybrid Glass, the measurements are always taken on the original device display. As already explained, all cutouts are important for the measurements. But the dimensions must also be accurately measured digitally. There are manufacturers who use dummy devices (without electronics, only device housing and display) for measurement. However, significant deviations from the original display can occur. For curved displays, Neoxum screen protectors are cut with the help of lasers so that neither the Neoxum protective film nor the Neoxum OnScreen Hybrid Glass protrude beyond the edges. In general, Hybrid Glass adheres more strongly to the display surface and is therefore very suitable for curved displays. An adhesive layer made of very thin silicone is responsible for the adhesion to the monitor surface. The adhesion is based on the physical principle of adhesion. We have already explained the adhesion based on forces in the nanometer range in more detail in an article on adhesion and adhesion of protective films on display surfaces.

Environmental impact screen protector

Prevention of electronic waste through high-quality display protection

Naturally, a high-quality screen protector ensures an extended device life because the control unit, the screen, is well protected. Broken or shattered device screens inevitably lead to expensive repairs or even device replacement. Often, it is simply too costly to repair the display because new devices cost almost the same. Consequently, broken displays or screens that have become unusable due to wear and tear or a display defect are ecologically very undesirable. Precautionary screen protection prevents display damage. Scratches and damage to the screen have no chance anymore, and in the event of a fall, the likelihood is much greater that a protected display will remain intact. The environmental impact is higher with screen protection than without.

Plastic recycling of display protection films

Display foils, on the other hand, are made of plastic. Inexpensive display protective foils made of PP, PE or PVC are not particularly resistant and therefore need to be replaced regularly. This in turn causes avoidable plastic waste. PP and PE can be recycled. Thermal utilization is also possible, leaving only water and carbon dioxide. However, we all produce far too much (cheap) plastic waste. It is better to use high-quality PET display foils, which are very robust and durable. In addition, PET display foils can be collected separately and recycled, for example, into beverage bottles. PVC protective foils have a rather poor ecological balance. PVC contains chloride (PVC = polyvinyl chloride), which reacts with health-hazardous dioxins, furans, and hydrochloric acid during thermal utilization (waste incineration). Therefore, exhaust gases contaminated with PVC must be cleaned using elaborate cleaning processes. In the long run, it is more sustainable to avoid inexpensive PVC display foils.

Apply a screen protector to the display

Dust-free environment

The essential rule when installing screen protectors or glass screen protectors is to take some time and ensure a dust-free environment. A dust-free environment can be easily created at home in the bathroom. After showering or bathing, the air in the room is relatively humid and there is usually little dust in the air. Alternatively, you can go into a well-ventilated room that is free from drafts. One should not wear linty clothing, such as a wool sweater.

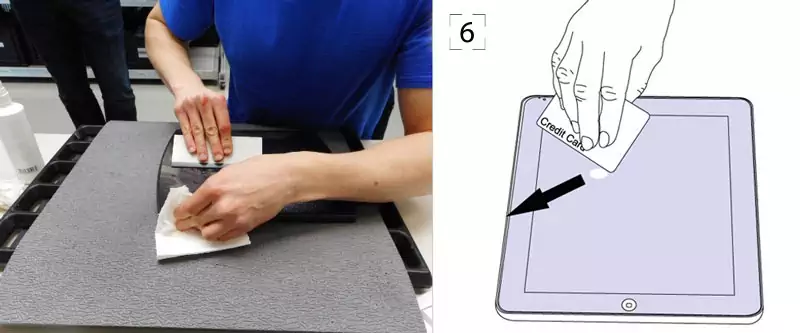

Cleaning the touchscreen

How a screen protector or also known as tempered glass, hybrid glass or glass film is carefully applied to the respective device display should be described in a detailed instruction manual for high-quality screen protection. The most essential aspect is that the monitor is free of grease and dust. Usually, a cleaning cloth is also included as an accessory with branded products. For this purpose, Neoxum provides a wet wipe for screen cleaning and a dry cloth with Neoxum display films, as well as OnScreen hybrid glass.

A microfiber cloth alone is not very suitable for removing fingerprints or grease. Armed only with a microfiber cloth, one would rather smear fingerprints on the display. In this case, it is advisable to use a suitable display cleaner liquid. Furthermore, it is recommended to clean the display from dust with the included cleaning accessories. Cheap microfiber cloths generate static electricity, which attracts even more dust to the display. In this case, it is advisable to also use an antistatic screen cleaning solution (screen cleaner) to remove dust.

Individual steps of the display protection assembly

Does the screen protector fit?

In the first step, start by placing the screen protector product, whether it's ultra clear or anti-glare, on the display to be protected to check the dimensions. Do all the cutouts fit? Are there cutouts for the camera lens, microphone, speaker outlet, etc.? Does the length and width fit? The backing film should not be removed yet!

IMPORTANT: Usually, the screen protector is cut slightly smaller than the dimensions from edge to edge of the display to make installation easier. The screen protector should be approximately 0.5-1 mm smaller all around than the display itself. This is to facilitate installation, depending on the size of the display.

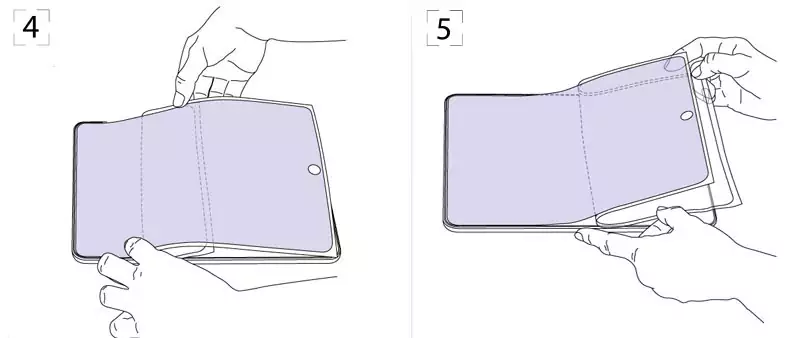

Partial removal of the carrier film

In the next step, a partial (approx. 2-4 cm) removal of the display protector from the carrier film will be carried out.

Different manufacturers have developed more or less unproblematic methodologies here to facilitate the removal of the actual display protection from the carrier film. All Neoxum products, display protection films, as well as OnScreen Hybrid Glass, are produced using the so-called Kiss-Cut process. In this process, all cut-outs are cut out. However, the outer contour is only laser-cut deep enough to accurately cut through the display protection material without also cutting through the underlying carrier film. The display protection can then be easily removed like a label. It is very important to touch the now exposed silicone adhesive layer as little as possible with your fingers.

Apply screen protector

The silicone-coated adhesive side of the screen protector is now placed on the cleaned, dust- and grease-free display surface at an angle of about 30-45° along one edge and carefully applied piece by piece to the touchscreen.

When using a screen protector larger than 15 inches diagonally, it is advantageous to align it along one of the long edges. At the same time, gradually peel off the backing film. This way, the glass display film or screen protector is applied to the surface without any air bubbles forming. Air bubbles can be smoothed out towards the edges using a thumb nail or a plastic card, such as a debit card.

If, despite all caution, a dust particle is found between the display surface and the screen protector after installation, it can be easily removed using a trick: Cut a piece of adhesive tape (approximately 5-7 cm long) from a brand like TESA or SCOTCH and stick it to the edge closest to the dust particle, with only one half attached to the screen protector. Then, lift the screen protector easily using the other unattached end. With a second piece of adhesive tape, which has been rolled into a loop with the sticky side facing outwards, the dust particle can now be removed from the display surface.